In the permanent makeup industry, the diversity of devices offered can be confusing or create uncertainty when choosing a model that will fully satisfy our needs and expectations. Every vendor advertises their products as the best, which is hardly surprising. The market for permanent makeup machines is highly developed; in store offers, we find devices ranging in price from 100 euros to several thousand.

Although it is known that price is one of the main factors determining the purchase, in this article we would like to highlight the key differences between cost-effective devices and those that require a greater financial outlay from the user. It is worth remembering that the price level reflects various aspects that are important to consider before finalizing the purchase.

Consistency and quality control during production are crucial. It is extremely important that each part is made with the utmost care and that the margin of error is kept low. Any problems with dimensions or quality of parts can negatively affect the operation of the entire machine. Buying ten low-quality machines of the same model does not guarantee that each will operate uniformly. This affects not only the quality of work but also has broader consequences.

Just like in pigment application techniques, where each stage is crucial and requires meticulous attention, so too does every component in the machine matter greatly. Nothing should be left to chance in the design of the device, so we will explain the differences between individual machines and discuss potential short- and long-term consequences for users.

PMU machines from the lower price range are often made from lower-quality materials, which affects their durability and may lead to frequent failures and replacements. Additionally, cheap motors often have problems maintaining constant speed and power, which is crucial for precision in permanent makeup. In the long term, these issues can generate additional costs related to repairs or replacement of the device. These devices also have a shorter lifespan and are often irreparable.

Some devices are additionally weighted with unnecessary elements to create a false impression of having more internal components. Attention should also be paid to incorrect specifications, such as the incorrect stroke of the device, which can affect the quality of pigment application. The needle mechanisms in low-budget machines are often poorly designed or made from easily worn components, further reducing work quality. These devices may also operate loudly and often lack necessary quality certificates, such as CE or UK/CA. Limited warranties and lack of technical support can additionally complicate usage in case of technical problems.

In the face of the pervasive trend of "fast fashion," which promotes the rapid purchase of cheaper product versions, we have focused on quality. From the very beginning of our machine creation process, the priority has been the quality of the device, its durability, and its efficiency.

By analyzing the specifics of production and understanding each of its stages, we realized that the project would require special attention. The complexity of each element and their mutual compatibility required numerous modifications and the introduction of improved technical solutions. From the motor, through every internal component, to the aluminum finish – everything was carefully thought out.

We decided to cooperate with the best component manufacturers, including Faulhaber, which, together with our engineers and programmers, developed motors perfectly tailored to the needs of PMU artists.

The advantage of our devices is that they were created in close cooperation with engineers and practicing PMU artists who fully understand what functions the machines should have, not only to enable the execution of perfect pigmentation but also to serve for many years. Each device is manually assembled by our skilled team in Europe, at our headquarters in Warsaw. Every component undergoes rigorous quality control before it is packaged and leaves our warehouse.

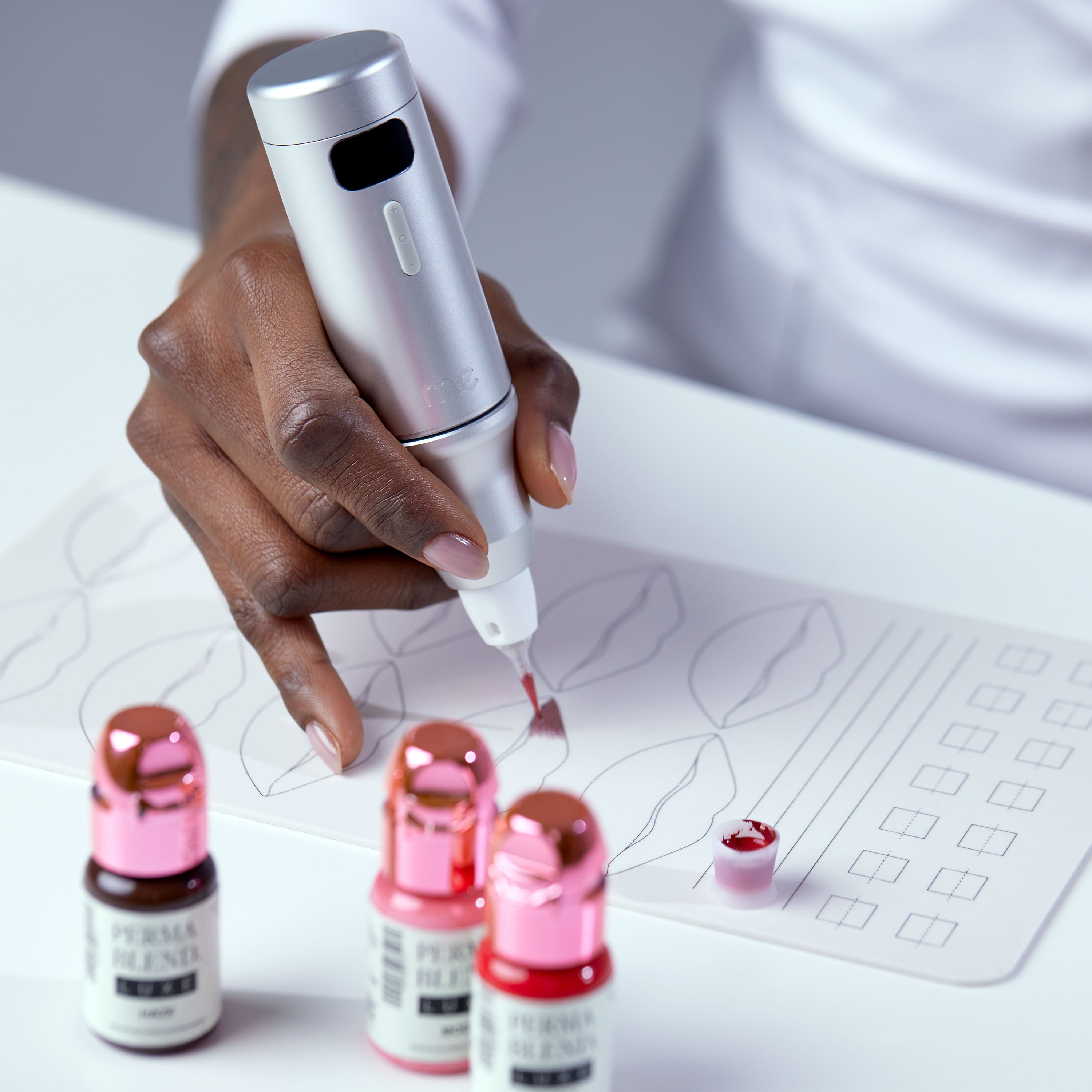

What sets us apart and contributes to the high quality of our wireless ME machine?

The ME model was developed from the ground up with perfection and precision in mind. Pigmentation starts with a single dot – and it was this detail that we focused on. From the beginning, understanding the importance of every individual stroke and dot was crucial for us.

After a thorough analysis of available devices and hours-long conversations with permanent makeup artists, as well as observing their work, we managed to create a device that meets the needs of artists at every level of use. The compatibility and precision of each component, the conscious choice of a brushless motor, the appropriate selection of the device's stroke length, the refinement of the device's softness and pusher mechanism, to ensure the pigmentation is as smooth and trouble-free as possible for the PMU artist. Achieving balance was incredibly important to us.

The quality and durability of the motor, quick customer service in case of problems, a 3-year warranty, appropriate software, the overall lifespan of the device, quality control of component production to ensure they are manufactured according to the design, component compatibility, the ability to work with universal cartridges, a larger stroke of 3.4 mm while maintaining the power and softness of the needle strike thanks to the pushing mechanism, high-class aluminum and the technology of making the device casing that allows for autoclave sterilization, OLED display, and CE and UK/CA certifications are just some of the features that demonstrate our commitment to delivering the highest quality equipment.

Although the temptation of a lower price may be strong, it is important to remember that choosing the right machine can significantly impact the success of your work.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.